By using our website, you agree that we make use of cookies to enhance your browsing experience with Gehring.

You are using a very outdated browser. To make full use of our website, we recommend that you update your browser to the newest version.

The hairpin technology specialists

The Gehring and copperING Group have united their global product portfolio and thus establish themselves as a supplier for production systems in both conventional and electrified powertrain segments. copperING is a pioneer of technologically innovative approaches and has extensive experience as a production technology manufacturer operating in the field of electric powertrains. The company‘s main focus lies in the fundamental processes involved in manufacturing stators and rotors for traction drives, the likes of which are used in the traction drives of electrified vehicles.

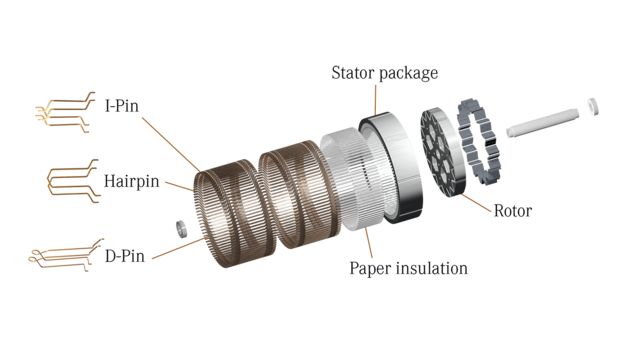

The company specializes in production technology for the manufacture of electric motors, based on I-pin, hairpin and D-pin technologies. These designs combine the efficiency of electric motors with high automation capabilities and process reproducibility – all of which are key requirements for series production in the automotive industry.

With standalone made-to-measure solutions for stator prototype development and small-scale series production, as well as fully automated new system solutions for electric motor production lines, copperING‘s product portfolio complements that of its new partner Gehring. The Gehring group therefore offers the full gamut of technologies for vehicle drives – from conventional solutions to hybrid technologies and even integral electrification.

Engineering Solutions for the development of electric motors

Developing electric drives and producing electric motor prototypes takes extensive knowledge of the interplay between individual production steps. We pass this knowledge on to our clients and support them from initial product development through to prototyping and all the way to series production.

Pin Production Machines

The planetary gearing (patent pending) of our pin production machines makes the individual pins ultra flexible. Thanks to the programmable axles, these can be bent into virtually any shape. To increase productivity, we can bend up to two units at the same time. Two grippers ensure wire is fed at a fast and constant speed, while the automated spool changer means production does not have to be interrupted. Cutting and chamfering within one processing step reduces the cycle time and makes pin insertion and pin welding easier.

E-Motive